- Digital solutions, Drinking water

Sainte-Germaine (Vendée)

Sainte-Germaine: a sustainable, self-sufficient water resource

In 2017, Stereau won the contract for the improvement of the treatment

process at the Sainte-Germaine catchment (Luçon – Vendée), entrusted by Vendée Eau.

Objective: to increase the production capacities of the facility both qualitatively and quantitatively, and to ensure decarbonation of the water for greater comfort

of the residents of Luçon and its surroundings.

The challenges

- To increase the treatment capacity of the Sainte-Germaine catchment from 160 to 250 m3/h to secure the supply of drinking water to Luçon and surrounding municipalities, which are more vulnerable during dry periods

- To improve the treatment process of the Sainte-Germaine catchment through pesticide treatment

- To implement a decarbonation unit at the plant to soften the water.

Our solutions

The Calcycle® process, developed and patented by Stereau, has been implemented at the facility to reduce the calcium hardness of the water. This process offers the dual advantage of beingenvironmentally friendly – as it does not discharge into the sewer system – and compact – as its footprint is limited. Compared to conventional decarbonation, it consumes fewer reagents and does not require additional sludge treatment equipment.

Benefits

- A high-quality drinking water thanks to a water decarbonation treatment.

- A simplified and cost-effective operation

- An exemplary environmental project thanks to the installation of photovoltaic panels producing green, decarbonized energy

- Long-term enhanced maintenance of the plant through the coupling of BIM with Vendée Eau’s CMMS (Computerized Maintenance Management System)

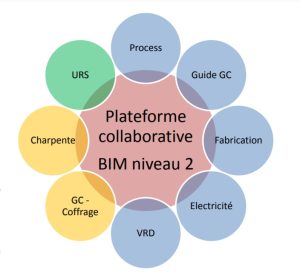

With the aim of optimizing the design and operation of its facilities, Stereau implemented the Building Information Modeling (BIM) methodology and digital modeling on this project. The work carried out using the shared model allowed all project stakeholders to have access to up-to-date documents at all times. The risks of design errors were controlled, as the impacts of modifying a structural element could be better understood, and potential conflicts could be immediately detected. The use of BIM had significant positive impacts on the entire life cycle of the structure, enabling Vendée Eau to optimize the operation and maintenance of its assets.